An effective dust collection system is essential for compliance with environmental regulations as well as for reducing clean-up. FESCO Direct sources highly effective dust collection systems from JEL Concrete Plants and WAMGROUP, the leading manufacturer of silo venting filters.

Designed and built by JEL Concrete Plants, this cement dust collector is specifically designed for dust collection from the truck mixer inlet zone in dry batch plants during filling of the truck mixer. It is equipped with zoned bags for simple and continuous operation, and can be easily installed in any concrete plant.

Features:

The Hopper Top Weigh Hopper Venting Filter by WAM® is a small cylindrical venting filter designed specifically for mechanically filled weigh hoppers in concrete batch plants. Dust is separated from the air flow by a single cartridge filter and then dropped back into the hopper after an automatic air jet cleaning system has removed the particles from the filter. A hinged top cover protects the filter from the elements.

Features:

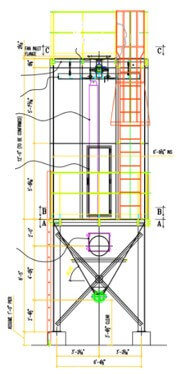

SiloTop ® Silo Venting Filters by WAM® are designed for venting pneumatically filled cement silos. Dust separated from the air drops back into the silo after the automatic reverse air jet cleaning system has removed the dust particles from the filter.

Features:

Whether you run a small concrete production business or a mid- to large-sized operation, FESCO Direct has a filtration system that will work with your plant. Let us know what equipment you have, or plan to have, and our engineers will recommend the most efficient filtration system for your operation.

JEL Concrete Plants is our partner concrete batching plant manufacturer - from stationary precast plants to fully mobile ready mix batching plants. Contact JEL Manufacturing and we'll help you source the equipment needed to build your plant exactly to your desired specifications.

Industrial high performance equipment for heating water, cooling water and generating steam in the rugged conditions of a concrete plant and other construction applications. Tailored precisely to your specific concrete plant and production needs.

Customize concrete production to its fullest: FESCO Direct manages the integration of silos, bins, hoppers, conveyors, bulk bag unloaders & powder handling into your unique system.

Maximize production. Minimize waste and mistakes. Automate your new or existing concrete plant with an automatic or manual control system specially engineered for your precast or ready mix concrete plant.

AL | AK | AZ | AR | CA | CO | CT | DE | FL | GA | HI | ID | IL | IN | IA | KS | KY | LA | ME | MD | MA | MI | MN | MS | MO | MT | NE | NV | NH | NJ | NM | NY | NC | ND | OH | OK | OR | PA | RI | SC | SD | TN | TX | UT | VT | VA | WA | WV | WI | WY