Adding a high-pressure washout system to your mixer can give you an extra 15 to 30 minutes of production time every day. This washout system works with all types of concrete mixers, and is easily installed. The rotating jets, high pressure pump and water reservoir are all built with quality materials and extremely reliable.

Ready-mix truck wash systems from Sioux are used to quickly and safely clean the concrete truck, including the hopper, of both front and rear discharge trucks. The concrete truck wash systems from Sioux are incredibly versatile and easy to use. The truck wash system can be changed to accommodate front or rear-discharging concrete trucks with the push of a button.

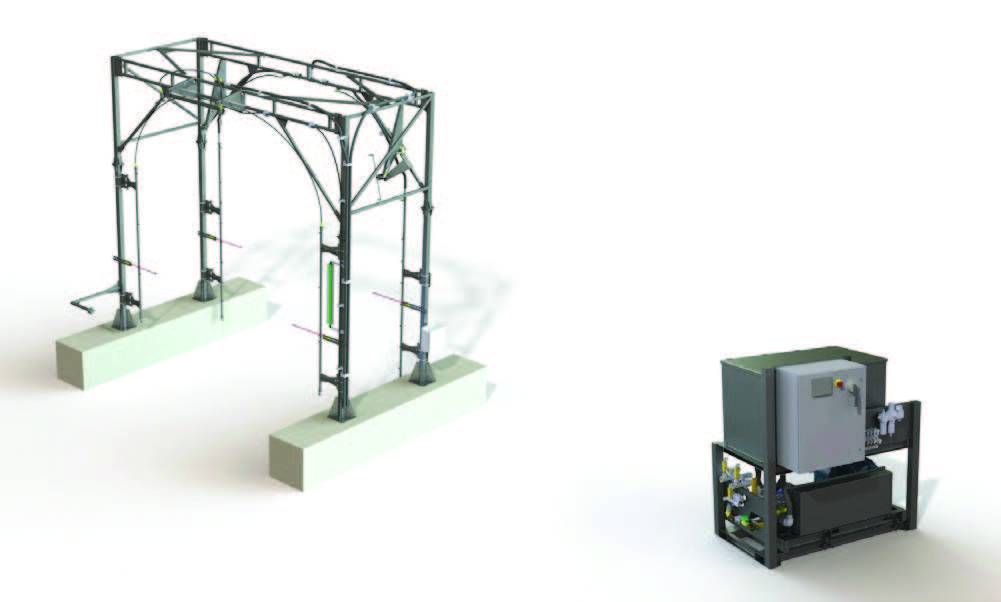

The truck wash system consists of two main parts, the TWR40 stainless steel wash tower and the TW40 power unit. The power unit supplies the water and power needed for the wash tower to effectively clean the concrete truck. The power unit features a large industrial pump that is capable of supplying 40 gallons per minute at 1200 PSI. When the truck approaches the wash tower a spray bar applies a detergent or cleaning chemical to the truck's sides. Then a series of rotary high-pressure spray nozzles clean the hopper to remove loose materials. When this process is complete, the truck will slowly proceed through the final set of spray bars that have high-pressure nozzles to clean and rinse the top and sides of the truck. A light bar assists the driver to determine proper positioning for each stage and counts down the time remaining in each cycle. Each truck is able to be cleaned in one minute.

The Cold Weather Package includes a temperature sensor to automatically activate winterization mode if the ambient temperature is near freezing. When enabled, only the hopper wash mode is activated to minimize ice build-up on the exterior of the truck and the wash pad area. An extended air blow down between cycles and hose insulation with heat tracing prevents water from freezing in the lines. This will help extend the length of time drivers are able to use the truck wash system in colder climates.

Concrete mixer washout systems save you money.

JEL Concrete Plants is our partner concrete batching plant manufacturer - from stationary precast plants to fully mobile ready mix batching plants. Contact JEL Manufacturing and we'll help you source the equipment needed to build your plant exactly to your desired specifications.

Industrial high performance equipment for heating water, cooling water and generating steam in the rugged conditions of a concrete plant and other construction applications. Tailored precisely to your specific concrete plant and production needs.

Customize concrete production to its fullest: FESCO Direct manages the integration of silos, bins, hoppers, conveyors, bulk bag unloaders & powder handling into your unique system.

Maximize production. Minimize waste and mistakes. Automate your new or existing concrete plant with an automatic or manual control system specially engineered for your precast or ready mix concrete plant.

AL | AK | AZ | AR | CA | CO | CT | DE | FL | GA | HI | ID | IL | IN | IA | KS | KY | LA | ME | MD | MA | MI | MN | MS | MO | MT | NE | NV | NH | NJ | NM | NY | NC | ND | OH | OK | OR | PA | RI | SC | SD | TN | TX | UT | VT | VA | WA | WV | WI | WY