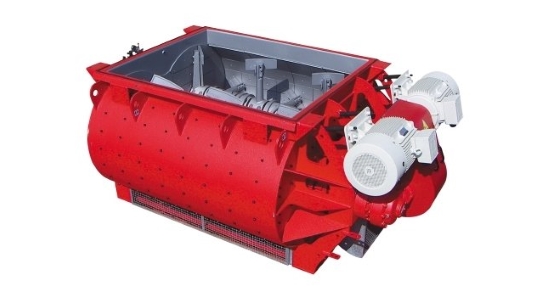

Twin Shaft Concrete Mixers

The SmartMix twin shaft concrete mixer combines an extra-rigid frame with a work-proven power train and innovative shaft seals built to last the life of the concrete mixer, making it ideal for high-speed production of wet precast, SCC and ready-mix concrete.

Because mixing is done above the concrete mixer floor, wear on the liner plates is very low. With its extra hard-wearing liner and paddles, high-efficiency gears and reliable shaft seals, the SmartMix has the lowest operating cost of any twin shaft concrete mixer on the market.

Why choose a twin shaft mixer?

Twin Shaft Mixers are the popular choice for paving and ready mix operations. These concrete mixers usually start around 3 cu. yards and go up to as large as 12 cu. yards. A twin shaft mixer is exactly as it sounds; two mixing shafts with several mixing paddles along each shaft that throw the material together. This aggressive mixing action results in a very homogeneous concrete mix in a very short period of time.

Twin shaft concrete mixers are so fast that it is not uncommon for owners to “double batch” using a smaller mixer and still maintain the same production as large drum mixer concrete plants. Not only do users of twin shaft mixers get a faster more consistent concrete mix; owners of twin shaft mixers have reported less cement usage in some circumstances for the same PSI and break strength as required when using a drum mixer.